CIVRO Matte Electro-Deposition (MED) is an innovative surface treatment process for aluminium profiles, based on the principle of electro-deposition. Originating from Japan, this technology's formula has been redeveloped by CIVRO. The texture of MED profiles is smooth and silky, reminiscent of porcelain, specifically designed to withstand severe climatic conditions. CIVRO MED outperforms competing products on the market in terms of both weather resistance and environmental protection.

CIVRO MED utilises pure nickel salts in its process for enhanced stability and environmental friendliness, distinguishing itself from other companies that commonly use tin salts, resulting in a cyan hue to the base material. While this approach reduces costs, impurities in tin salts can lead to harmful exhaust gases and waste during aluminium profile manufacturing, posing environmental risks.

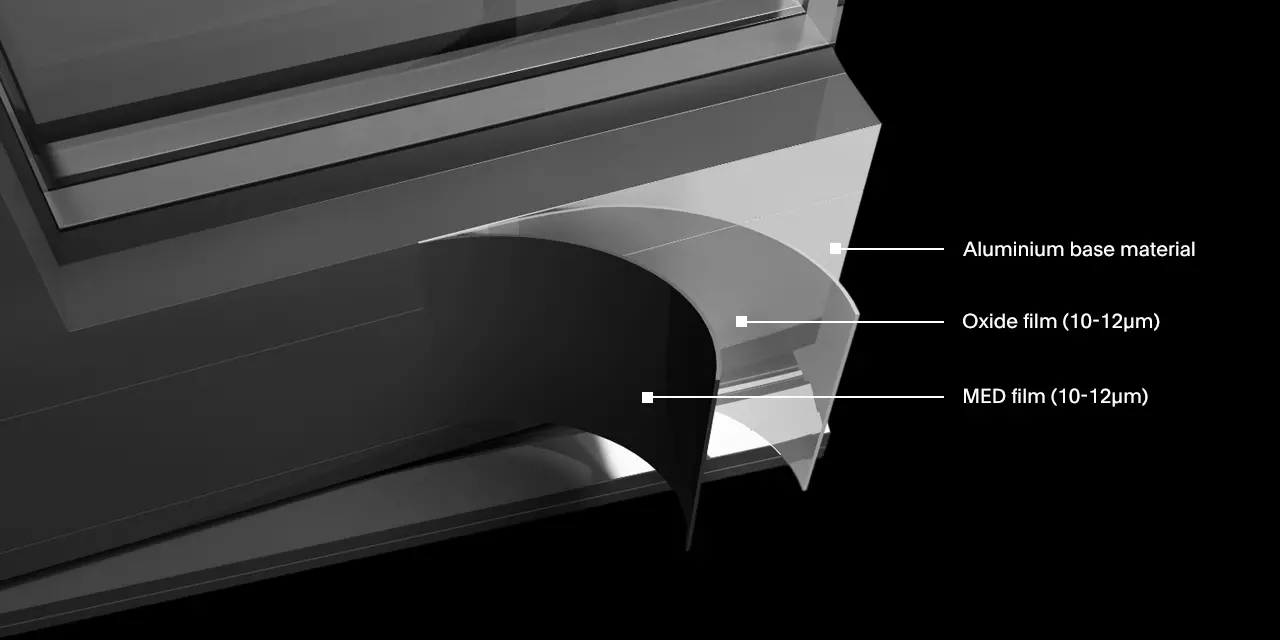

The oxide film thickness of CIVRO MED profiles is 10-12μm, combined with a 10-12μm Electro-Deposition (ED) film, resulting in an overall composite film thickness of 20-24μm and alkali resistance exceeding 300 hours. In comparison, similar products on the market typically feature only a 7μm ED film with alkali resistance of around 24 hours. Due to its superior weather resistance, CIVRO MED profiles are widely applied in harsh environmental conditions such as coastal cities with high humidity and salinity, regions experiencing high temperatures and humidity, and cities with significant seasonal temperature variations.