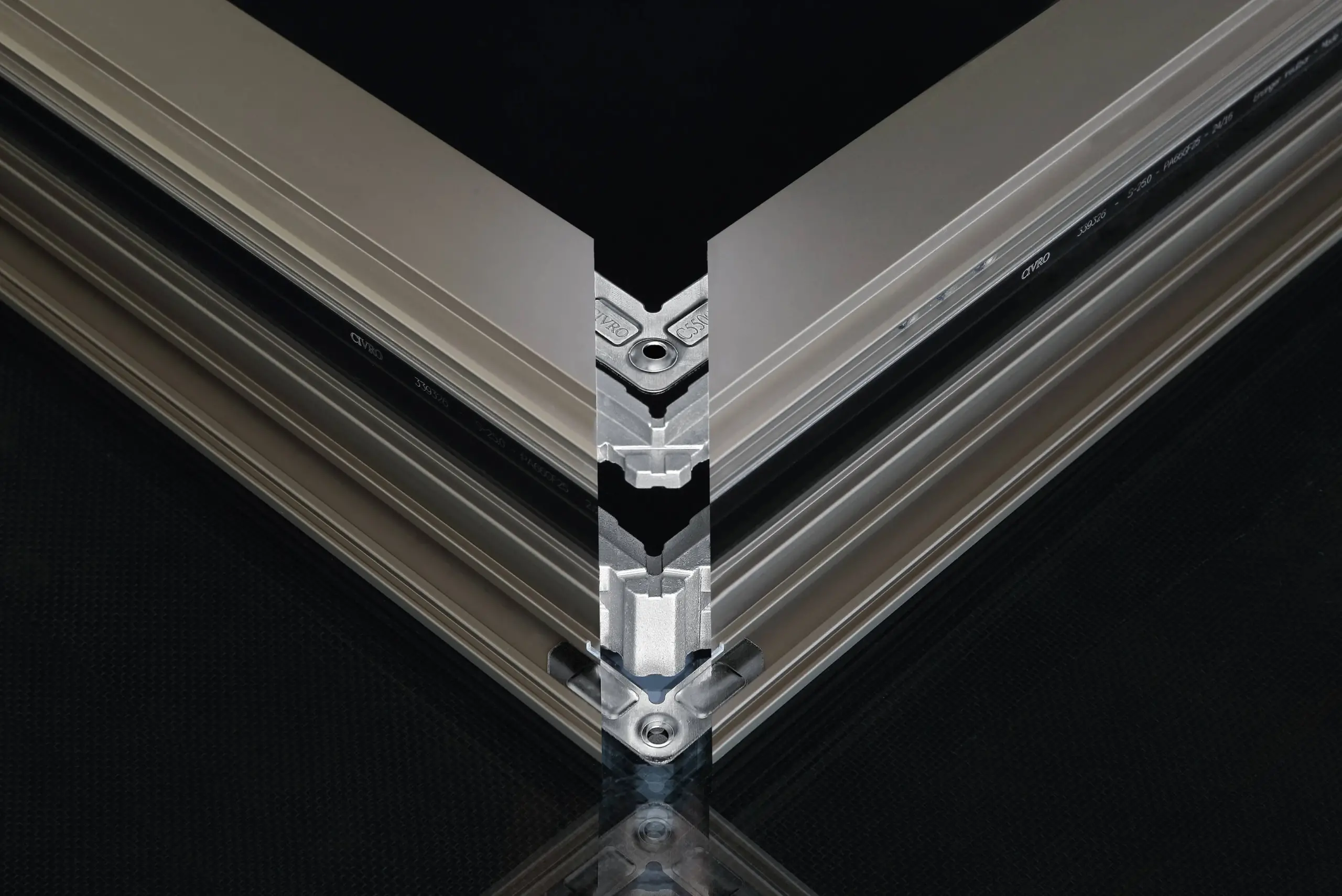

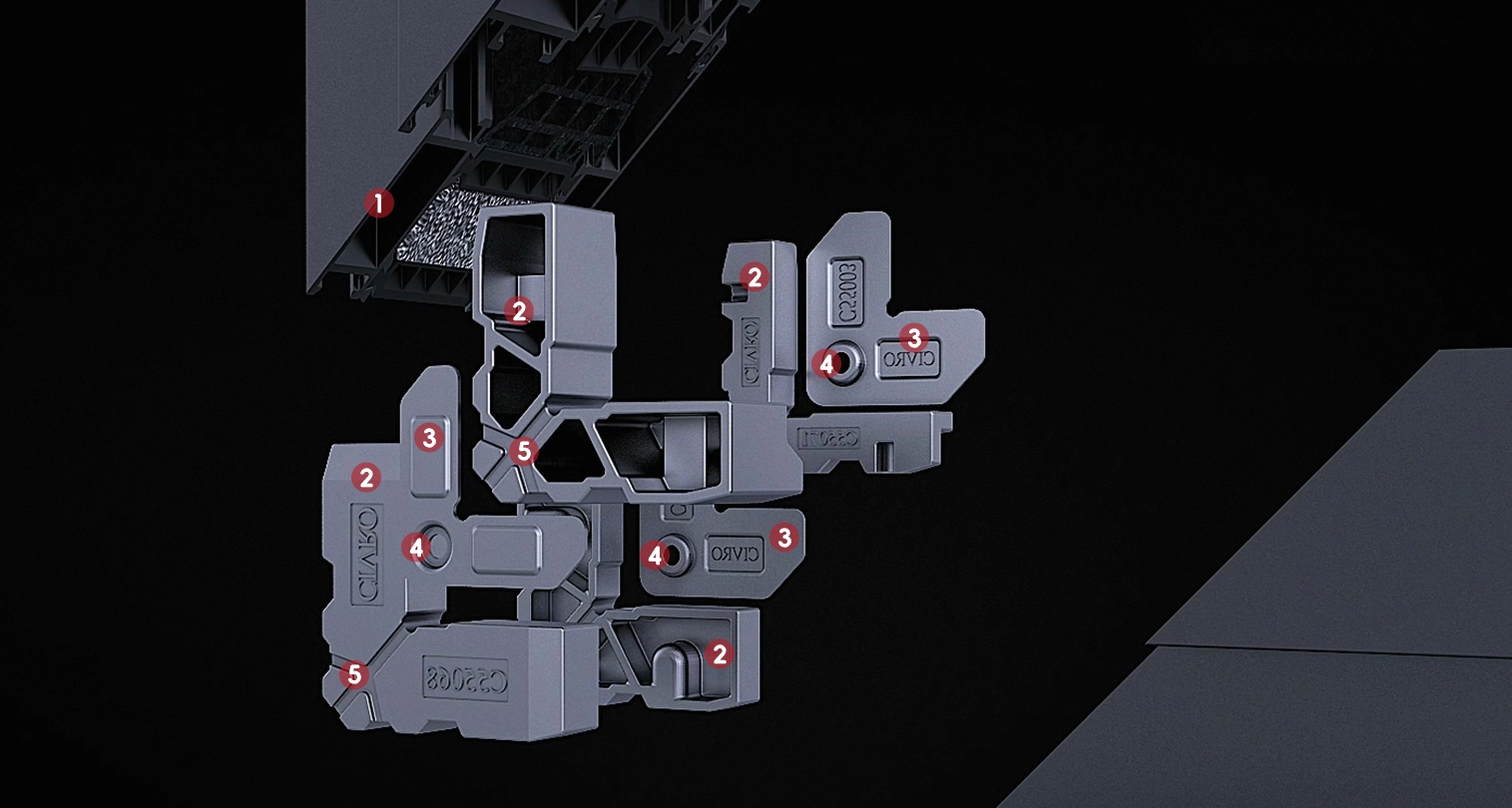

Corner bonding in aluminium window manufacturing refers to the process of joining the corners of the aluminium profiles together using adhesive bonding techniques rather than traditional mechanical fasteners like screws or rivets.Comparing with traditional corner joint technique, CIVRO’s new method of corner bonding process typically involves cleaning and preparing the aluminium surfaces, inserting tailored CIVRO one piece die-casting preservative-treated aluminium corner brackets, applying several kinds of specialised adhesive, and then securely clamping the corners together until the adhesive cures.